Top 8 Green Manufacturing Trends for 2022

Table of Contents

The last two decades have resulted in many changes in every financial sector throughout the world. This is in particular genuine for the producing field.

Several of the variations had by now been carried out ahead of the start out of the pandemic. Many thanks to the pandemic, a lot of of these are becoming utilized to fantastic impact. These changes have been kicked into substantial gear thanks to elements these as instability in the provide chain, significant need for items and modifying client requirements.

Inexperienced Developments to Look at for in 2022

1. Clever digital thread

Large producers have adopted IoT and IIoT to kickstart sensible manufacturing techniques. These ‘digital threads’ engage in a crucial role in bettering operational efficiencies, increase product high-quality and in transform brand loyalty. Organizations are now soliciting buyer inputs to boost consumer knowledge with improvements and design and style improvements recommended by finish people. Establishing thorough electronic threads will not only outcome in inexperienced production practices but high-quality goods as properly. This is feasible thanks to safe digital platform connectivity.

2. Sustainability

Suppliers are also spending shut attention to sustainability as well. Sustainability by using environmental, social and governance policies are no extended just watchwords. Providers are investing in scalable systems to improve their manufacturing method to decrease source use when creating significantly less squander.

3. A lot more onshore producing

To help you save expenses, sourcing supplies for manufacturing was outsourced to China and other nations around the world. The pandemic has disrupted the source chain and there is no very clear thought when the offer chain will be reset to the pre-pandemic stage. Making use of materials created in-place will produce additional work opportunities and decrease dependence on overseas sources whilst reducing shipping and delivery expenses. This is heading to just take priority in 2022.

4. Shifting target from B2B format to B2C

Brands are now focusing much more on B2C to present the end buyer reduced priced items and to keep brand name command. Brands have tons of things to target on with purchaser experience excellent in intellect.

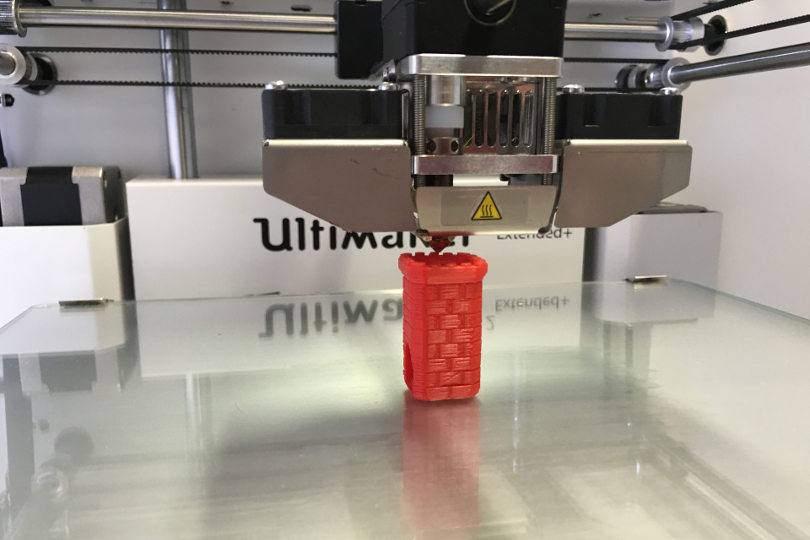

5. 3D Printing

Also termed additive producing, 3D printing is going to be a large factor in 2022. Some of the positive aspects made available by this strategy are liberty to design and style, tailored merchandise and goods which conduct better. This form of manufacturing promotes cost-effective price ranges, sustainable process and most critical of all, a shorter time to market. This procedure is being actively utilized in the automotive and aerospace sectors.

6. Amplified use of automation

Automation has been in use for a when in a couple of industries with PID controllers and PLCs. Wit the availability of rapid pcs and lots of specialized software package offers, automation has stepped in to fill the void from worker shortages. Automated processes are now in use not just on the manufacturing facility floor but also in the back office environment. Technological innovation and clever machines are serving to with fantastic conclusion earning, product quality and consistency.

7. Predictive servicing

Technological innovation and automation are again filling a gap and eradicating guesswork. Predictive upkeep packages monitor troubles and notify managers of complications in the producing process. Scheduled maintenance of machinery and areas replacement is also finished so that there is quite little downtime. This final results in main fees personal savings which can then be handed on to the conclude person. Digital transformation is the way to apply this and other this sort of systems.

8. Place of work talent

The adoption of automation and other systems in production implies that the workforce will have to be technologically knowledgeable. Tech significant industries like automotive and aerospace will want access to a expertise pool which is common with present-day methods. A lot of corporations are working with vocational schools so that they have the suitable persons on the work.

Conclusion

Significantly of the improve in production is pushed by purchaser input these days. End customers want to know how their merchandise were being created and what elements were being employed. With a spike in power and raw materials prices, corporations will have to also offer with environmental and other laws.

Customers are driving the adjust in direction of sustainability and firms are having their social responsibility seriously. The good thing is, engineering is assisting to make a large amount of these decisions and modifications probable. Brands are keenly informed of the link amongst their brand name picture, producing techniques and earnings.

Accessibility to systems like AI, robotics and blockchain will basically shift the way merchandise are built.