Lumos System: AI-Powered Quality Control

Table of Contents

The automated process of high quality manage in generation permits you to observe the most important procedures, excluding the human element. Thus, on any solution line and at any time, the quality of solutions remains the exact and fulfills the requirements.

Lumos is a Rios robotic good quality control process that selects solutions with flaws in any production chain, is simple to take care of and deploy, so it is at the moment actively made use of in many industries. It is suited even for food business enterprises.

Why do you Require Excellent Regulate in Generation?

Automation good quality manage has many rewards:

- Significant productivity

- Compliance with high quality specifications

- Rising the degree of production

- Reduction of idle time on lines and the volume of waste.

In addition, the production excellent manage software has a effortless interface so that it is straightforward for the personnel to navigate the administration method and configure robotic answers for the distinct needs of the manufacturing unit.

What are The Rewards of Workcell Lumos?

Lumos is a robotic high quality regulate resolution acceptable for monitoring any output line. At the exact same time, the robotic technique routinely transmits all the important data to the consumer in genuine time without any delays.

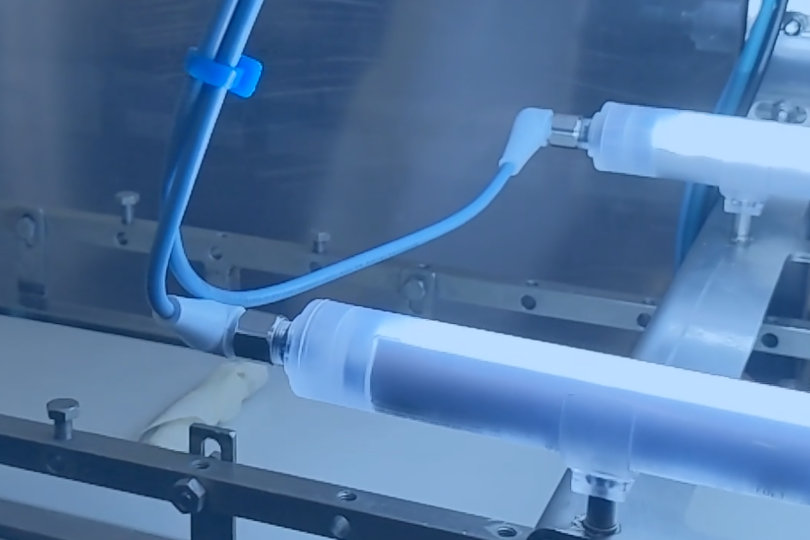

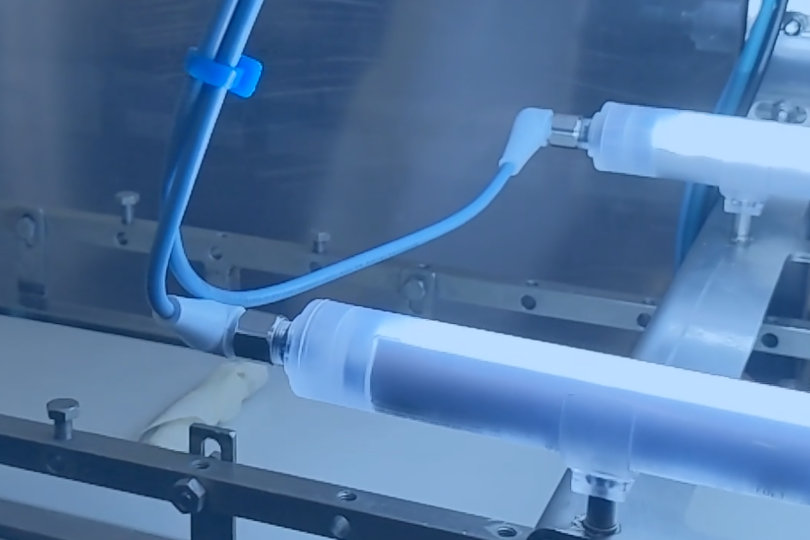

AI-eyesight, which is the basis of the high quality regulate resolution, checks and measures every single corner of the merchandise. The software collects and procedures all the info, supplying a in depth report. In the upcoming, such details aid to optimize processes and make completed products and solutions even better.

Technical Characteristics of Lumos

The productivity of the Lumos robotic from Rios is extraordinary: in a moment, the robotic processes 100 models of goods, detecting problems centered on AI.

Lumos robotic excellent manage is integrated into both new and existing production strains. The technique is flexible and quick to spot, so it is rather practical and profitable. In addition, Lumos is utilized as a connecting line or can work with an output conveyor. The business can integrate a new control process at any phase: both of those in advance of the start off of the manufacturing facility and when the factory is currently in operation: the alternative integrates with other technologies and is common. Moreover, the system adapts to any dimension and variety of solution.

Hold in mind that Rios gives its units and products and services as a RaaS, which suggests that you can customize your factory to your requires, and it will be inexpensive.